The Remerging Battle Between 182 And 210: What Modules Are Really Needed For Full Grid Parity?

- 20/10/15

- Business of Solar

Following the silicon wafer size controversy in the first half of the year, the mass production controversies of Longi, Jinko Solar, and JA Solar surrounding 182 modules have once again moved into the spotlight. Despite these controversies, large-size silicon wafer is still the strategy recognized by the entire industry today as the means to achieve grid parity for the photovoltaic industry.

There are currently two strategies for large-size silicon wafer. The first is more conservative, designed to meet the maximum value of compatible size after the upgrade of existing equipment. This approach increases the silicon wafer size to 182mm and increases the power of 72 wafers to 535Wp.

The second strategy is more innovative: a new 210mm size silicon wafer is used to increase mass production power to 545Wp. This increases the power of the module significantly (by as much as 23%) compared to the 445Wp at 166mm. And compared to the 535Wp module at 182mm, the power increases 10W while the module area remains constant. In addition, the power of the 210 series module – which has just 55 battery cells – can exceed the power of the 182 series which has 72 battery cells.

|

|

Production Power |

Size |

Number of Battery Cells |

Weight |

Open Circuit Voltage |

Operational Current |

|

182 Modules |

535W |

2256*1133mm |

144 |

32.3kg |

49.5V |

13A |

|

210 Modules |

545W |

2384*1096mm |

110 |

32.6kg |

37.9V |

17.24A |

N.B.: The data in the above table is compiled based on published documents from two manufacturers

The controversy over whether modules can reduce the levelized cost of energy per kilowatt-hour should be analyzed and addressed with the holistic view of the system in mind. The theoretical cost calculation of a certain part does not bear practical value. After all, in meeting the challenge of grid parity not only do module companies bear the burden of cost reduction and efficiency enhancement but the entire system including, inverters and trackers, needs to be upgraded in a timely fashion to take into account key trends in the industry.

With this holistic view in mind, a well-known local design institute took three modules (210, 182 and 166) and selected Daqing, Heilongjiang province, Laizhou, Shandong province, and Xingning, Guangdong province as the measurement sites (using the flatness of the ground as the key variable to select string inverters). With a 100MW power station as a baseline, a detailed comparison was made on the cost of the low-voltage side of the power station system, and the size and performance parameters of the three modules were based on the specifications of representative manufacturers. The schematic diagram of the square matrix is as follows:

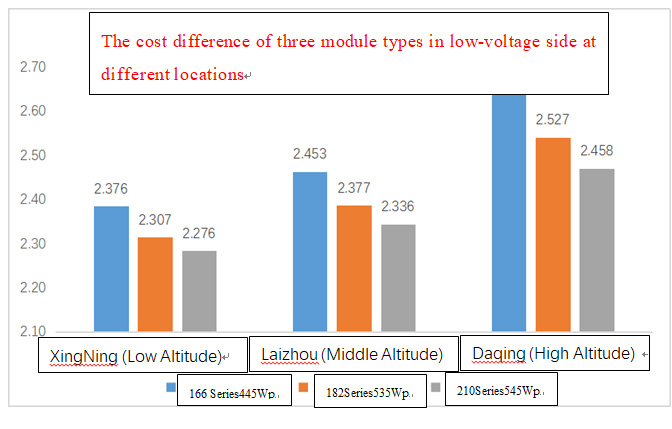

Based on three module parameters and three regional conditions, the costs of low-voltage side construction associated with three modules in the different regions are also varied. The difference is illustrated below:

In general, the costs of the low-voltage side associated with the three modules decreased significantly with the increase in power. The 545Wp module using 210mm silicon wafer has the lowest overall cost under different latitude conditions. Compared to the 166-type 445Wp module, the reduction is between 0.1-0.17 yuan/watt; while compared to the 182-type 535Wp module, the reduction is between 3-7 minutes/watt.

Taking the Daqing project as an example, the adoption of the two-row vertical mounting design of string inverters and trackers resulted in an increase in module power. In addition, the increase of module power can save the number of trackers, pile foundations, cables, and string inverters. Please see below for specific sub-item cost difference:

|

High Latitude Daqing |

Wafer Type |

166 Module 445Wp |

182 Module 535Wp |

210 Module 545 Wp |

|

Module (Block, W) |

1.6 |

1.6 |

1.6 |

|

|

Land (Mu) |

0.016 |

0.016 |

0.015 |

|

|

Base Concrete/M3 |

0.036 |

0.030 |

0.027 |

|

|

Drilling Cost |

0.049 |

0.039 |

0.035 |

|

|

Foundation Steel Bar/Ton |

0.020 |

0.017 |

0.015 |

|

|

Foundation Embedded Parts/Ton |

0.046 |

0.038 |

0.029 |

|

|

Tracker (Tons) |

0.442 |

0.353 |

0.329 |

|

|

Inverter (Set) |

0.134 |

0.134 |

0.134 |

|

|

Inverter Tracker/Kg |

0.002 |

0.002 |

0.002 |

|

|

DC Cable (1×4) |

0.033 |

0.028 |

0.021 |

|

|

Inverter Sent Out (3×185) |

0.208 |

0.235 |

0.217 |

|

|

Total |

2.630 |

2.527 |

2.458 |

High Latitude Area - Daqing, Heilongjiang province - Comparison of the cost difference between the three modules (unit: yuan/Wp)

Similarly, the test tables of the two projects in Xingning, Guangdong province and Laizhou, Shandong province are as follows:

|

Middle Latitude Laizhou |

Wafer Type |

166 Module 445Wp |

182 Module 535Wp |

210 Module 545 Wp |

|

Module (Block, W) |

1.643 |

1.636 |

1.643 |

|

|

Land (Acre) |

0.009 |

0.009 |

0.008 |

|

|

Base Concrete/M3 |

0.030 |

0.025 |

0.022 |

|

|

Drilling Cost |

0.039 |

0.034 |

0.029 |

|

|

Foundation Steel Bar/Ton |

0.015 |

0.012 |

0.010 |

|

|

Foundation Embedded Parts/Ton |

0.046 |

0.038 |

0.029 |

|

|

Tracker (Tons) |

0.339 |

0.290 |

0.262 |

|

|

Inverter (Set) |

0.134 |

0.134 |

0.134 |

|

|

Inverter Tracker/Kg |

0.002 |

0.002 |

0.002 |

|

|

DC Cable (1×4) |

0.024 |

0.021 |

0.016 |

|

|

Inverter Sent Out (3×185) |

0.172 |

0.175 |

0.181 |

|

|

Total |

2.453 |

2.377 |

2.336

|

Middle Latitude Area - Laizhou, Shandong province - Comparison Of The Cost Difference Between The Three Modules (Unit: Yuan/Wp)

|

Low Latitude Xingning |

Wafer Type |

166 Module 445Wp |

182 Module 535Wp |

210 Module 545 Wp |

|

Module (Block, W) |

1.645 |

1.645 |

1.636 |

|

|

Land (Acre) |

0.006 |

0.006 |

0.006 |

|

|

Base Concrete/M3 |

0.023 |

0.023 |

0.015 |

|

|

Drilling Cost |

0.031 |

0.031 |

0.024 |

|

|

Foundation Steel Bar/Ton |

0.009 |

0.009 |

0.006 |

|

|

Foundation Embedded Parts/Ton |

0.046 |

0.046 |

0.029 |

|

|

Tracker (Tons) |

0.306 |

0.306 |

0.242 |

|

|

Inverter (Set) |

0.134 |

0.134 |

0.134 |

|

|

Inverter Tracker/Kg |

0.002 |

0.002 |

0.002 |

|

|

DC Cable (1×4) |

0.022 |

0.022 |

0.010 |

|

|

Inverter Sent Out (3×185) |

0.153 |

0.153 |

0.173 |

|

|

Total |

2.376 |

2.307 |

2.276 |

Low Latitude Area - Xingning, Guangdong province - Comparison Of The Cost Difference Between The Three Modules (Unit: Yuan/Wp)

As the design institute commented in its report: “According to our specific calculations in the three locations, high-power modules can indeed result in cost savings if they’re provided with string inverters. Although the extent of the cost savings varies from location to location, the general idea of using high-power modules to reduce the low-voltage side cost is absolutely valid. Since different projects have different topographic characteristics, installation difficulty and system configuration, we suggest analyzing and calculating the details according to specific project conditions.”

A staff member from the design institute is convinced that on the basis of high-power modules and string inverters, the low-voltage performance of the 210 mm series modules is impressive. The lower voltage can push the power of a single string to approximately 20KW. In recent years, no-one has spared any effort to increase overall power to reduce the cost of electricity and so, the use of low-voltage modules has provided a new strategy for cost reductions.

Source: Photovoltaics 9.17 Manuscript

Relevant Topics

Smart Energy Solutions

delivered straight to your inbox

More Events